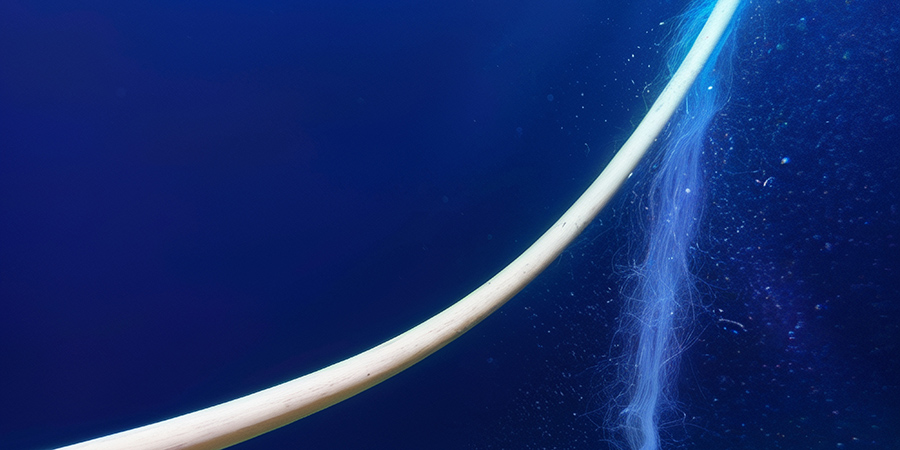

Subsea cables are the backbone of global connectivity, and these undersea networks are essential for internet access, international communications, and energy transmission.

Despite their importance, subsea cables face numerous challenges. They are susceptible to physical damage from fishing activities, anchoring, and natural disasters such as earthquakes and underwater landslides. Additionally, the cables are vulnerable to deliberate sabotage, as evidenced by recent incidents in the Baltic Sea where suspected sabotage disrupted power and communication lines. Repairing these cables is a complex and costly endeavor, often requiring specialized ships and equipment, leading to prolonged downtimes and significant financial losses.

To address these vulnerabilities, self-healing technologies have been developed. Innovations include materials that can autonomously repair minor damages, thereby enhancing the resilience and longevity of subsea cables.

Investing in self-healing technologies represents a significant step toward ensuring the uninterrupted operation of critical infrastructure, both above and below waters, in an interconnected world.

Self-Healing Technologies in Practice

Advancements in self-healing technologies are revolutionizing the durability and maintenance of subsea cables. Three notable innovations in this field include microcapsule-infused insulation, self-healing fiber optic sensors, and fluid-filled, self-repairing cables.

Microcapsule-Infused Insulation

SINTEF, a Norwegian research organization, has developed an innovative insulation material incorporating microcapsules filled with liquid monomers. These microcapsules are designed to address "electrical trees," which are microscopic channels that form within insulation materials under electrical stress, potentially leading to short circuits.

When such stress-induced channels reach the microcapsules, they rupture, releasing the monomer that fills and polymerizes within the channels, effectively halting further degradation. This self-repair mechanism enhances the lifespan and reliability of high-voltage (HV) subsea installations, reducing maintenance costs and downtime.

Self-Healing Fiber Optic Sensors

Researchers have also developed flexible fiber optic sensors utilizing a core-cladding structure made from polymerizable deep eutectic solvents (PDES). These sensors exhibit high transparency, flexibility, and a broad operational temperature, ranging from -27°C to 156°C. The supramolecular network within the PDES core provides self-adhesion and optical self-healing properties, ensuring stable signal transmission even after physical damage.

The hydrophobic cladding further allows these sensors to function reliably in underwater environments, making them ideal for long-term subsea structure monitoring.

Fluid-Filled, Self-Healing Cables

Northern Powergrid, in collaboration with the Energy Innovation Centre and Gnosys, has also introduced self-healing, fluid-filled power cables to reduce environmental impact and maintenance costs. These cables utilize a mixture of tung oil and metal soaps that, upon exposure to air due to a leak, form a cohesive mass sealing the breach. This self-healing fluid (SHF) mimics the natural clotting process, effectively preventing further leakage and environmental contamination. The implementation of SHF is projected to save Northern Powergrid up to GBP 20 million over five years by minimizing repair needs and associated environmental damage.

Collectively, these innovations signify a substantial leap forward in enhancing the resilience and sustainability of subsea cable systems. By integrating self-healing materials and technologies, the industry can expect reduced maintenance costs, extended service life of installations, and minimized environmental risks associated with cable failures.

Distributed Fiber Sensing (DFS) and Vibration Detection and Ranging (VID+R)

DFS technology transforms existing fiber optic cables into continuous sensors capable of detecting temperature changes, strain, and vibrations along the entire cable’s length. The VID+R component enhances this by identifying and classifying external threats, such as anchor drags or fishing activities, in real time. This proactive monitoring allows operators to respond swiftly to potential damages, reducing repair costs and service interruptions.

Synaptec's Refase Technology

Synaptec has developed 'Refase'—a distributed sensor system that utilizes existing optical fibers within subsea cables to monitor electrical performance across multiple locations. By sending and reflecting light signals, Refase can detect faults and automate responses within milliseconds, enabling unaffected sections to resume operation promptly. This rapid fault detection and isolation minimizes downtime and maintenance costs.

ThayerMahan's SeaScout System

ThayerMahan’s SeaScout system uses high-resolution synthetic aperture sonar (SAS) paired with advanced artificial intelligence (AI) algorithms to detect and classify potential damage to subsea cables before it leads to failure. By processing ultra-detailed sonar imagery, the system can spot anomalies early, enabling proactive maintenance and helping minimize service disruptions and repair costs.

CLEMATIS Integrated Monitoring System

The CLEMATIS project, funded by Innovate UK, introduced a multifunctional distributed sensor system to monitor subsea cable infrastructure. By integrating acoustic and thermal sensing capabilities into existing optical fibers, the system can detect temperature variations, mechanical stresses, and external disturbances like anchor strikes. This holistic approach ensures early fault detection and precise localization, enhancing maintenance efficiency.

Material Innovations

Advances in materials science are paving the way for next-generation, self-healing materials and coatings tailored for subsea cable applications. Researchers are increasingly turning to nanotechnology and intelligent coatings capable of sensing and responding to environmental stressors in real time. These innovations aim to significantly boost the durability and resilience of underwater cable systems.

One promising example is self-healing polyurea coatings, which can rapidly restore mechanical strength after damage. This built-in recovery mechanism offers ongoing protection against corrosion, helping extend the operational life of subsea cables while reducing maintenance needs.

Collaborative Efforts

The advancement of self-healing technologies for subsea applications benefits significantly from collaborations between the industry and academia. Eelume AS and the Norwegian University of Science and Technology (NTNU) have exemplified how partnerships and academic research can drive subsea robotics innovation.

Additionally, international cooperation frameworks, such as the Quad Partnership for Cable Connectivity and Resilience, are bringing together countries such as Australia, India, Japan, and the United States to enhance the protection and resilience of submarine cables through shared research and policy development.

Call to Action

To future-proof the backbone of global digital and energy infrastructure, the industry must accelerate the development and deployment of self-healing technologies in subsea cables. By uniting the efforts of researchers, industry leaders, and policymakers, we can build smarter, more resilient subsea networks that safeguard connectivity for generations to come.

Now is the time to innovate boldly, collaborate widely, and commit to a future where underwater infrastructure heals itself before any failure strikes.

Navigating the Depths: Overcoming Multinational Challenges in Subsea Cable Projects